OUR AQUAPONICS LOCK DOWN PROJECT

Can aquaponics offer a more productive, cost effective and environmentally friendly approach to growing food for all of us?

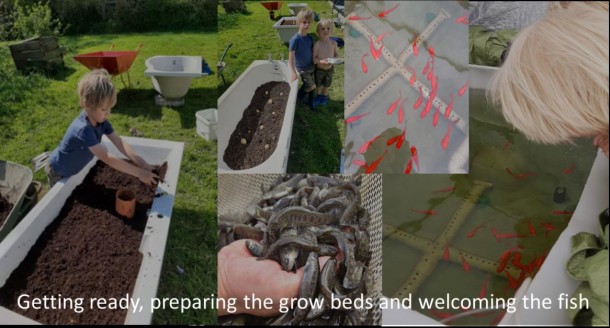

We’ve been growing our own veg at home for a few years now, but during lockdown we decided to develop an idea I’ve had for a while to also bring in fish (trout & goldfish) into our garden polytunnel using a system called aquaponics.

Aquaponics is potentially a great alternative way of producing our own (organic) food in a more sustainable and safer way, which could save us money too if we get it right. We think this could be an exciting new form of small scale local farming, particularly where land and water is limited. So we’re trying it out, in our small way, to contribute to the understanding of how this could work.

And it’s been quite inspiring… This summer we have created our own small (nearly) self-sufficient productive ecosystem in our garden, mainly from reusing recycled and donated components and drawing on guidance and skills from friends. It’s become very educational for the boys (one of our schooling lockdown projects!) and we’re having fun doing it all too.

“The way to get started is to quit talking and begin doing.” Walt Disney.

Overview of the system and our Big Idea

In technical terms, we have built what’s called a Recirculating Aquaculture System, RAS for short. This is a low tech and extremely water efficient solution which has the potential to significantly increase food productivity rates.

‘Recirculating’ means we are continually reusing the same water for both the fish and growing plants. Fish poo turns into nutrient rich plant food (with the help of bacteria) which is pumped to the grow beds, which in turn clean and filter the water back for the fish. It’s totally symbiotic!

On the downside, RAS systems can be expensive to run as they can be very energy demanding as they rely on pumping water around the various circuits, supplemented by aeration and UV clarifiers which also consume energy.

For us, this means we’re growing and eating food that hasn’t been produced using chemicals and without incurring any food miles, as we’re growing it all at home.

Our Big Idea is to focus on energy performance

The big idea for our system, over time, is to try and reduce down the amount the energy the system consumes as much as we possibly can, whilst enhancing food productivity rates. The aim is to try and develop our approach to help make aquaponics as affordable as possible for anyone to operate.

To enable this, we’ve set up the system to be a demonstration. We’ve included many of the components that may be included within an aquaponics system (and also equally applicable to most energy consuming systems we see within workplaces). This includes lighting, process and motor loads, a (basic) control and monitoring system, while also generating renewable electricity from solar photovoltaic panels and providing top-up water from rainwater harvesting.

It’s a multi-loop system, using smaller more efficient modular pumps and other systems components, rather than it all being on one pumped loop circuit with single much larger systems components. This design gives us more flexibility and options for control over the different elements and to try different performance improvement ideas out as our experience and knowledge develops.

A multiple loop system basically means we have multiple pumped circuits pumping water to various ponds and grow beds, within the polytunnel and outside, and then the water uses gravity to return to our central sump tank which houses all the system pumps.

With a typical approach to design, we’ve created what we think a typical system may look like, using modern efficient pumps but with oversized components to allow for future expansion i.e. this is just like how most of us design any energy service system we’re involved with at work. A typical RAS system for trout would also typically have at least two ponds, to be able to separate fish of different ages.

We believe this could potentially make a good example for continually optimising energy performance more generally.

The maximum operational budget we’ve set ourselves is equal to the feed in tariff payments we receive for the 1.7kW PV system we’ve tapped into. Any additional electricity we require will be sourced on a green tariff from Green Energy UK. Any additional water provision will come from our village water supply.

In time, the aim is for the system to generate some additional income to at least match the operational expenditure, while being non-profit making.

Ultimately, our long-term goal for the polytunnel system is to also be a ‘Net Zero Carbon’ energy system, consuming equal to or less energy than it produces.

Adding local small scale renewable energy and water components makes managing the resources use more complex as they’re all on the same site. However, this is important for the demonstration as this is the way many of our energy systems are going, even at home.

The learning has just started for all of us.

How we went about it

In April 2020, we started planning out what we needed to do to modify our garden polytunnel to accommodate fish.

We already had various components in place that we could reuse, but we needed to also focus on some key task, which included the following:

- Plumb in new fish tanks and create pumped water loop circuits linking the fish tanks and grow beds to a central sump tank.

- Add in an outside circuit to capture rainwater and to help control water temperature if the polytunnel overheats in summer.

- Link the system to new potato and carrot grow beds (located outside in recycled bathtubs).

- And to make it all absolutely safe for our two boys who were going to be key workers for the project!

The initial work took us about 8 weeks to complete for us to get ready, by doing a little bit every day.

To do this successfully, we were very much guided by an aquaponics proficiency course lead by Antonio from Bioaqua trout farm (in Somerset). Antonio and his family are now one of the UK’s specialists in aquaponics having set up and optimised their own commercial system which I believe is still the largest aquaponics trout farm in Europe.

A big thank you goes to Antonio for sharing his knowledge and experience with all of us.

Sourcing zero or low polluting materials

One of the things we have to be especially careful about is to only use materials that wouldn’t be poisonous to fish. Everything we use needs to be zero polluting in terms of metals, volatile organic compounds (VOCs) and other chemicals, etc. This is quite hard to do when we’re using lots of donated and recycled components – so we need to find out as much as possible about previous uses and the make-up of what we use.

We’ve learnt, for example, that old ABS waste pipe doesn’t stay stable within the polytunnel environment so we’ve already had to replace some of the pipework we’d original put in. An example of learning as we go.

Welcoming the fish

Before we could bring in fish, we had to get our system first registered with the UK’s Centre for Environment Fisheries & Aquatic Science (CEFAS) for managing biosecurity. This gives us the site registration number we need to be able to buy and transport live fish.

In June, we were finally able to welcome our first fish, introducing 50 young goldfish into our smaller tank; this was quite a stressful start as the fish had to be posted (because of lockdown) and they got delayed on route…

The arrival of the fish meant that we could finally start our aquaponics adventure!

Later on, we have since added 70 ‘fingerling’ (finger sized) trout which now reside in our main pond. The trout were thankfully personally delivered by Gerard from Plaistow Mills Trout Farm (North Devon). Gerard has also been inspired to set up his own aquaponics system (to be incorporated into his trout farm) so we’ve buddied up to support each other in our ventures.

The fish numbers we have started with means our set-up is at a very low density for aquaculture (up to approx. 10 kg of fish per m3 water volume within the fish tanks). We potentially could double these numbers and capacity in time, using the existing tanks we have whilst still keeping our set-ups low tech. Staying ‘low tech’ is a key part of our strategy for keeping energy consumption down whilst ensuring good standards for fish health.

A special thanks also goes to those others who have helped in the set-up and experience so far.

Like most things, getting this done would not have been possible without it being a team thing.

As well as those already mentioned above, particular thanks also goes to the following, to name just some of the people who’ve contributed in some way:

- Charlie for the hard work helping me build the hydroponic water tanks, ponds and pond covers (to keep the boys safe).

- Alan (Ali’s dad) and Rob for donating a couple of IBC 1000 litre water containers (that were excess to their farm’s requirements).

- Sam (aka Sam Davies Plumbing) for locating and dropping off discarded bathtubs (to be used for grow beds) and for doing some of the ‘loose-end’ plumbing.

- Roger W for donating the first bathtub which kicked off the idea.

- Guy M. for very importantly ensuring the system electrics are safe and compliant, and more recently helping me to add in a basic automated control and monitoring system (to help look after it all whenever we’re away).

- Ian for donating the paving slabs being used for the flooring.

- Specialist Aggregates for the recycled scallop shells used on the floor inside and outside the polytunnel, acting as a barrier protecting the system from the slugs!

- John M. for looking after the fish so well during the few occasions we’ve been away so far this year.

- And lastly, and most importantly, Jack and Barney Brittain for all their hands-on work in making this happen, planting all the veg seeds and helping to look after the fish (and letting me create a lockdown school project out of this…). And of course to Ali, as always, for all her amazing patience with another one of my mad endeavours…

Our experience operating the system so far

Over the course of the summer, the system has produced over 22kg of veg for us along with some oversized (dwarf) sunflowers, marigolds, poppies and other flowers. All grown from fish poo!

As it’s still very early days for our system so, so far, we’ve mainly focused on leafy green veg within the polytunnel itself. This has included successfully growing leafy greens, leaf beat, lettuces, kale, rocket, spinach, chard, French beans, mangetout, spring onions, shallots and courgettes and a few small pumpkins.

At the peak of the summer, we were picking enough French beans and mangetout to eat them practically every day; luckily we really like our green veg!

Viruses, infectious diseases and health

One of the challenges we had initially was sourcing an adequate disinfectant early on in lockdown. This delayed bringing in the fish because we wanted to make sure the tanks were clean and safe.

Health and safety for aquaponics, like many processes, has to be a key priority. We need to be mindful of infectious diseases that could impact on fish health as well as our own, whilst following food safety guidelines and good practices.

When we experience with slightly different ways of doing aquaponics, we need to monitor water quality and make regular visual checks on fish welfare. We also need to keep out and manage pests as much as we can.

The key (measurement) parameters we are focusing on to ensure good fish welfare and plant growing conditions are water temperature and water pH.

- As temperature rises and dissolved oxygen decreases, fish begin to experience stress. Rainbow trout can start to feel stress at water temperatures above 20°C.

- A pH level of around 7 is a good target to meet the needs of both the fish and plants.

We are also making regular checks for any water ammonia and nitrite levels (both poisonous for fish) and nitrates (that makes the plants grow!).

Continually improving our skills and performance

Over the summer, we have been rapidly developing our knowledge and skills in rearing fish, maintaining the bacteria levels that the system needs, balancing all this with what plants require to grow, and more generally keeping on top of the water chemistry so everything thrives. Every day is a school day, as they say, learning through experience as we go.

This all sounds a lot to do… but we’ve discovered we can manage it all in, on average, just 20 minutes a day… this is my one of my prerequisites for being an everyday champion (rather than a specialist) in something that we do.

Now we have the overall system up and running, we are now ready to start measuring and monitoring the input resources the system consumes, as well as system status and outputs, set our energy performance baselines and look to continually improve overall performance going forward.

We will continue to record how well we do.

What are the key components of the system?

On a more detailed level, our system so far comprises the following:

- 1,000 litre fish tank (recycled IBC container) for the goldfish and 4,000 litre fish pond for the trout. We are planning to add another fish tank in 2021.

- Six plant grow beds (in old bath tubs) operated and controlled to regularly flood and drain. The bath tubs are wrapped in insulation (using old offcuts) to help dampen changes in water temperature.

- The grow beds are filled with clay insulation pellets, to act as the growing medium for both plants and the bacteria we need, supported by garden and tiger worms that we’ve added.

- Two 1000 litre hydroponic water tanks with plants growing on rafts; this uses deep water culture where plants roots feed from nutrient rich water.

- 4,000 litre Sump tank, located at the lowest point in the polytunnel, which houses the system pumps.

- In energy terns, we use two fish pond pumps, two grow bed circuit pumps, two UV clarifiers, two air pumps and sensor probes to help us monitor water pH and water temperature.

- Recent addition is our (basic) automatic control and monitoring system. This auto-switches the pumps on a float switch (Iocated in the sump tank) when the water level is too low. The monitoring system also raises an alarm on event of power failure and/or low water levels.

- All the above is housed within our polytunnel, with includes provisions for (manually operated) passive environmental control by opening up the side vents.

- Outside we have an additional water circuit which includes two more hydroponic water tanks and one more filled with clay pellets. This outside circuit captures rainwater and also provides a water cooling circuit during periods of hot weather.

Some future plans

We have space within the polytunnel for an extra support tank for the fish, which would be used periodically during system cleaning. We’re already rethinking the design of the tank to be more effective at extracting the fish poo and creating overall better water flow within the tank for healthier fish…

The boys have made a special request for future growing of peppers and tomatoes. Both of these crops would need very high levels of nutrients. We are looking at ways of creating some mini greenhouses (using old windows from our house) for such future crops which would be drip fed from the aquaponics system.

Our imagination is racing! Anything is possible…

If you’re interesting in finding out more, or coming to visit us and the polytunnel set-up down in Devon at any stage, please get in touch.

Comments